Machine Quilting Thread Shreds, Then Breaks

by Kathy

(Kansas City, MO)

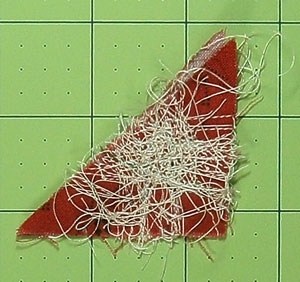

The top thread breaks. An inspection of the broken end of the thread shows that one of the thread strands have broken and bunched up while remaining strands stayed threaded through the needle for a short time before breaking. Why is this happening?

Reply

It sounds like your thread is shredding.

It's a really frustrating problem, but there are a number of possible reasons for what's causing the problem.

Remember, after each adjustment, test on a quilt sandwich made from the fabrics in your quilt.

- Re-thread your sewing machine. If that's the problem, it was a simple fix.

- Insert a new needle. Needles are the root cause of a number of sewing machine problems. It's easy to check, just change to a new, fresh out of the pack needle. An imperfection in the needle eye could be causing the thread to shred.

- Use a quality thread. Make sure it's not the thread, itself. The major thread manufacturers do a good job and in the scheme of things, the cost of thread just doesn't add that much to the cost of a quilt.

- Use the proper spool pin. If you're using a cone of thread, make sure you're using a separate metal thread stand. Thread on cones is meant to be pulled up and off the spool from the top. A metal thread stand does just that.

Conversely, spools of thread that are wound straight onto the spool (the strands of thread will look like they are stacked one on top of each other--not crossed)should be used on the vertical spool pin on your sewing machine. That is how they are intended unwind off the spool.

- Check the needle thread tension. Look at the stitches you've already put into your quilt sandwich.

Does any bobbin thread show on the top? That is the sign that the needle thread is too tight. To reduce tension, reduce the tension setting number or turn the knob to the left (remember 'lefty-loosey', 'righty-tighty'). Most tension adjustments can be made with the needle tension alone.

- Check the thread path to make sure that your thread isn't catching on something. Thread will sometimes wrap itself around the spool pin or uptake lever of your sewing machine, increasing the needle tension until the thread snaps.

Are you using a spool with a notch in one end? If you are using a horizontal spool pin, make sure the notched end of the spool is to the right so that the thread doesn't catch on it.

- Increase the needle size for higher thread count fabrics. Are you using a batik or other high thread count fabric? Increased thread count creates more friction as the thread passes through the quilt sandwich. This rubbing may fray the thread.

Switch to a larger needle of the same type (i.e. if you're using a Microtex Sharp 80/12, switch to a Microtext Sharp 90/14).

You want a needle just large enough to get the thread through the fabric without breaking, but not so large as to leave unsightly holes.

- Finally, check your throat plate for burrs. These are little nicks that happen when the needle hits the throat plate instead of going through the hole...like when we accidentally sew over and hit a pin. Or during free motion quilting when the quilt sandwich is pulled too fast and hard and pulls the needle out of position so it hits the plate.

If it's a burr, you might be able to rub the burr out with Crocus cloth, but I don't have any of that sitting around. (It's a cloth used for sanding on fine parts.) I bet you don't either.

If you can't saw out the burr, then you'll need to replace your throat plate. I use both a straight stitch and a zig zag stitch version for different quilting applications, so I've always got an extra one handy and I can identify if it's a burr.

If you're free motion quilting and your thread breaks always when quilting in one particular direction, there's a good probability that it's a burr.

If after all this, your thread is still breaking, it's time for a visit to your sewing machine dealer for a check up.

One year at Christmas, I was making quilts for everyone in the family and, of course, started

after Thanksgiving.

As I would pull the stitched pieces out from under the needle to cut the threads, I wasn't raising the needle uptake arm to its highest position (and thereby opening the tension disks). Because there was tension on the thread as I pulled it out, it wore a groove into the bobbin mechanism that interrupted the flow of thread. It caused my thread to keep breaking. It was a simple repair job and took just a few of days. But REALLY bad timing.

The moral of my problem...just remember to have your uptake arm in the highest position when you are pulling on the thread in any way!

I hope one of these suggestions fixes your problem.

Let us know how it goes.

Piecefully,

Julie Baird

Editor